Make the future with advanced technology and quality.

Chemical

We will lead the bright future of the materials industry.

Products

- Calcined Alumina

Alumina, a white crystallized powder, is made by calcining aluminum hydroxide and the chemical formula is Al₂O₃. It is widely used typical α-Alumina (Corundum). It is commonly used for flame retardants, insulating materials, spark plugs, IC boards, abrasives, brighteners, etc. because of its high melting temperature, high mohs hardness, high electricity resistibility, stable reactivity to acid and alkali.

■ KC Part

| Product Name | CA-83F | CA-50F | SA-50D | SA-50S | SA-SC |

|

|---|---|---|---|---|---|---|

| Chemical roperties |

Al₂O₃(%) | MIN 99.6 | MIN 99.6 | MIN 99.6 | MIN 99.6 | MIN 99.6 |

| Na₂O(%) | MAX 0.30 | MAX 0.35 | MAX 0.30 | MAX 0.36 | MAX 0.30 |

|

| Fe₂O₃ (%) | MAX 0.025 | MAX 0.025 | MAX 0.025 | MAX 0.020 | MAX 0.025 |

|

| SiO₂(%) | MAX 0.02 | MAX 0.02 | MAX 0.02 | MAX 0.025 | MAX 0.02 |

|

| Loss on lgnition(%) | MAX 0.10 | MAX 0.10 | MAX 0.10 | - | MAX 0.10 |

|

| Physical Properties |

Moisture(%) | MAX 0.10 | MAX 0.10 | MAX 0.10 | MAX 0.1 | MAX 0.1 |

| Dp50(㎛) | 60±10 | 50±10 | 55±10 | 50~70 | 55±10 |

|

| +45㎛(%) | MIN 60 | MIN 40 | MIN 50 | - | MIN50 |

|

| Specific surface area(㎡/g) | 0.3~0.7 | 0.3~0.7 | 3~7 | 17~22 | 17~22 | |

| Angle of Repose | 48~53 | 50~55 | 38~43 | - | - | |

■ KA Part

| Product Name | Dp50 (㎛) | Na₂O(%) | SSA(㎡/g) | |

|---|---|---|---|---|

| Normal Soda Serise |

KSA-S | 50 ± 10 | 0.26 ~ 0.38 | 3 ~ 5 |

| KMS-100 | 86 ~ 105 | MAX 0.3 | 4 ~ 6 | |

| Low Soda Serise |

ULS-200 | MIN 80 | MAX 0.025 | 0.5 ~ 3.0 |

| KLS-100 | 80 ~ 105 | MAX 0.05 | 1 ~ 3 | |

| KLS-1 | 50 ± 5 | MAX 0.05 | MAX 5.0 | |

| KLS-5 | 45 ~ 105 | MAX 0.05 | 0.9 ~ 1.2 | |

| Fine Alumina Serise |

KAM-A | 3.5 ~ 4.0 | MAX 0.35 | 0.9 ~ 1.3 |

| KAM-C | 4.3 ~ 4.6 | |||

| KAM-02 | 2.5 ~ 3.5 | |||

| CA-5M | 4 ~ 5 | |||

| KES-N1 | 1.1 ~ 1.3 | MAX 0.30 | 4 ~ 7 | |

| KES-N2 | 1.1 ~ 1.3 | 3 ~ 5 | ||

| KES-51 | 1.4 ~ 1.9 | MAX 0.05 | 1.7 ~ 2.2 | |

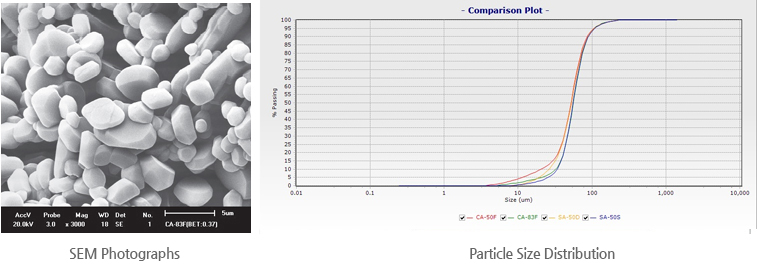

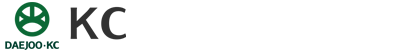

- Calcined Alumina KC part

As CA-83F, CA-50F are calcined Alumina of a hexagonal structure, they are widely used for refractories, ceramics, abrasives, etc. The fine particle content is lower than others and the unit crystal size is 3-5㎛. SA-50D is used for manufacturing sintered alumina or spinel. The unit crystal size is 0.5~1.0㎛.

■ Product Data

| Product Name | CA-83F | CA-50F | SA-50D | SA-50S | SA-SC |

|

|---|---|---|---|---|---|---|

| Chemical Properties |

Al₂O₃(%) | MIN 99.6 | MIN 99.6 | MIN 99.6 | MIN 99.6 | MIN 99.6 |

| Na₂O(%) | MAX 0.30 | MAX 0.35 | MAX 0.30 | MAX 0.36 | MAX 0.30 |

|

| Fe₂O₃ (%) | MAX 0.025 | MAX 0.025 | MAX 0.025 | MAX 0.020 | MAX 0.025 |

|

| SiO₂(%) | MAX 0.02 | MAX 0.02 | MAX 0.02 | MAX 0.025 | MAX 0.02 |

|

| Loss on lgnition(%) | MAX 0.10 | MAX 0.10 | MAX 0.10 | - | MAX 0.10 |

|

| Physical Properties |

Moisture(%) | MAX 0.10 | MAX 0.10 | MAX 0.10 | MAX 0.1 | MAX 0.10 |

| Dp50(㎛) | 60±10 | 50±10 | 55±10 | 50~70 | 55±10 |

|

| +45㎛(%) | MIN 60 | MIN 40 | MIN 50 | - | MIN50 |

|

| Specific surface area(㎡/g) | 0.3~0.7 | 0.3~0.7 | 3~7 | 15~25 |

5~7 |

|

■ Uses, Application

(1) Fused Alumina, Mullite, Spinel

(2) Refractory Brick, Castable

(3) Sintered Alumina, Ceramic Fiber

(4) High Alumina, Ceramics, Whiteware

(5) Abrasives

■ Packaging

(1) BULK

(2) Flexible Container Bag( 1,000kg)